© janaka dharmasena dreamstime.com

Application Notes |

iCoupler Technology Benefits Gallium Nitride (GaN) Transistors in AC/DC Designs

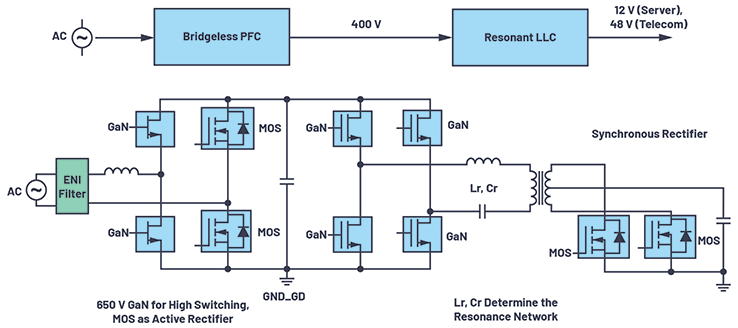

Highly efficient ac/dc power supplies are key to the evolution of the telecom and datacom infrastructure, as power consumption grows rapidly due to hyperscale data centers, enterprise servers, or telecom switching stations. However, the power electronics industry has reached the theoretical limit of silicon MOSFETs.

Meanwhile, recent gallium nitride (GaN) transistors have emerged as a high performance switch to replace silicon-based MOSFETs, offering increased energy conversion efficiency and enabling greater density. A new isolation concept with new specifications is required to address the advantages of the GaN transistors. GaN transistors can switch much faster than silicon MOSFETs and can achieve lower switching losses due to:

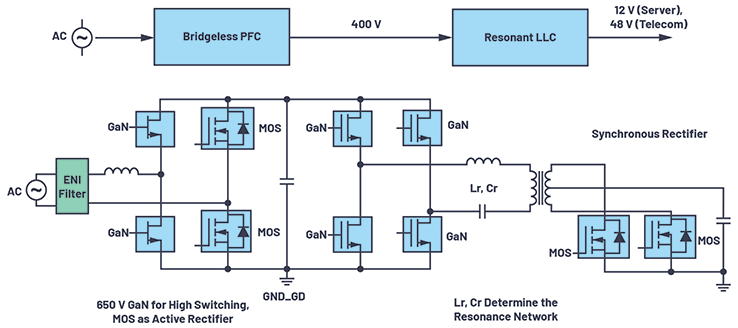

Figure 1. Typical ac/dc power supply for telecom and server applications.

Typical Isolation Solutions and Requirements

UART Communication Isolation

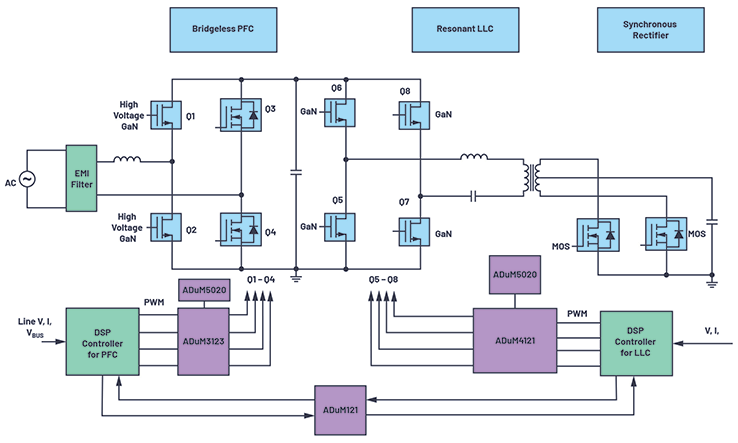

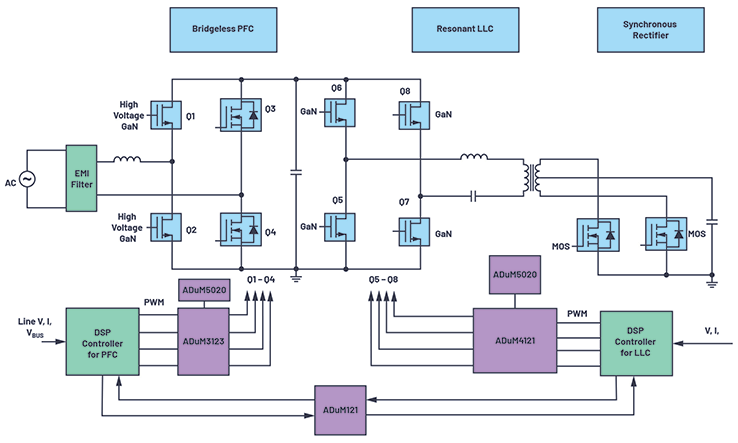

The change from a previous analog controlled system to a DSP controlled system requires the isolation of the pulse-width modulated (PWM) signals and the additional control signals. The dual-channel ADuM121 can be used for UART communication between DSPs. To minimize the total system size required for the isolation, the epoxy resin sealant is used in board assembly. Smaller size and high power density are critical in the evolution of ac/dc. Smaller package isolators are required.

PFC Section Isolation

The propagation delay/skew, negative bias/clamp, and size of the ISO gate driver is critical for GaN in contrast to MOS. To drive a half-bridge or full-bridge transistor with GaN, the ADuM3123 single-channel driver can be used for the PFC section and the ADuM4223 dual-channel driver for the LLC section.

Powering the Devices Behind the Isolation Barrier

Based on ADI’s isoPower® technology, which is designed for power transfer across the isolation barrier, the ADuM5020 is a compact chip solution that can match a GaN transistor’s auxiliary power supply with that of a gate.

Isolation Requirements

Table 1. Comparison of Different Methods in Driving a GaN Half-Bridge Transistor

Figure 1. Typical ac/dc power supply for telecom and server applications.

Typical Isolation Solutions and Requirements

UART Communication Isolation

The change from a previous analog controlled system to a DSP controlled system requires the isolation of the pulse-width modulated (PWM) signals and the additional control signals. The dual-channel ADuM121 can be used for UART communication between DSPs. To minimize the total system size required for the isolation, the epoxy resin sealant is used in board assembly. Smaller size and high power density are critical in the evolution of ac/dc. Smaller package isolators are required.

PFC Section Isolation

The propagation delay/skew, negative bias/clamp, and size of the ISO gate driver is critical for GaN in contrast to MOS. To drive a half-bridge or full-bridge transistor with GaN, the ADuM3123 single-channel driver can be used for the PFC section and the ADuM4223 dual-channel driver for the LLC section.

Powering the Devices Behind the Isolation Barrier

Based on ADI’s isoPower® technology, which is designed for power transfer across the isolation barrier, the ADuM5020 is a compact chip solution that can match a GaN transistor’s auxiliary power supply with that of a gate.

Isolation Requirements

Table 1. Comparison of Different Methods in Driving a GaN Half-Bridge Transistor

To take full advantage of a GaN transistor, the preferred requirements for isolated gate drivers are:

Figure 2. Typical ISO opportunity and requirement showing the UART isolation and PFC section isolation in isoPower devices.

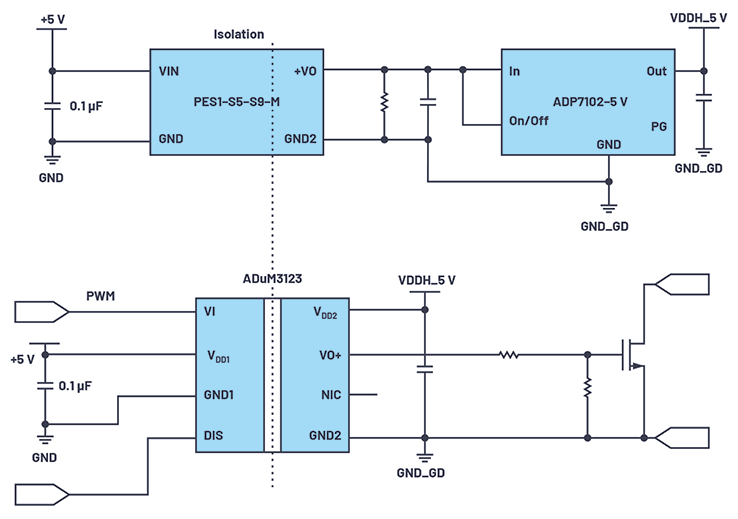

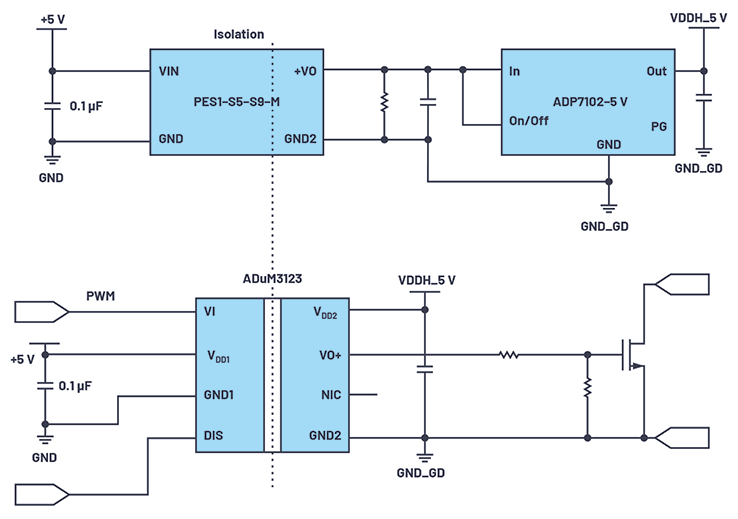

Single-channel drivers are ready for GaN transistors. A typical single-channel driver is the ADuM3123, using external power supplied by Zener diodes and discrete circuits for negative bias (optional) as shown in Figure 3.

Figure 2. Typical ISO opportunity and requirement showing the UART isolation and PFC section isolation in isoPower devices.

Single-channel drivers are ready for GaN transistors. A typical single-channel driver is the ADuM3123, using external power supplied by Zener diodes and discrete circuits for negative bias (optional) as shown in Figure 3.

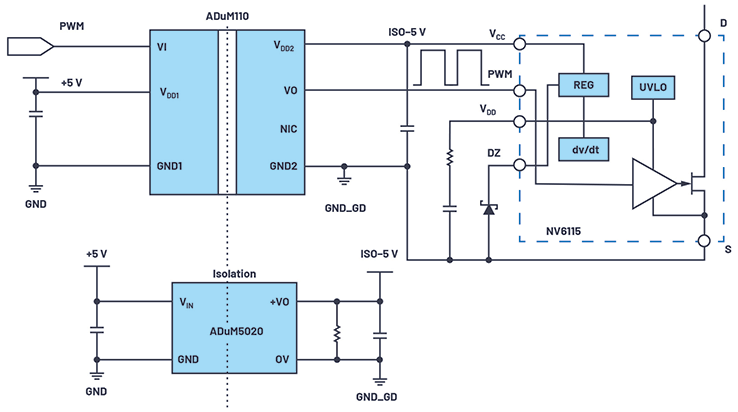

Figure 3. A single-channel, isolated isoCoupler driver application overview for a GaN transistor.

New Trend: Customized, Isolated GaN Modules

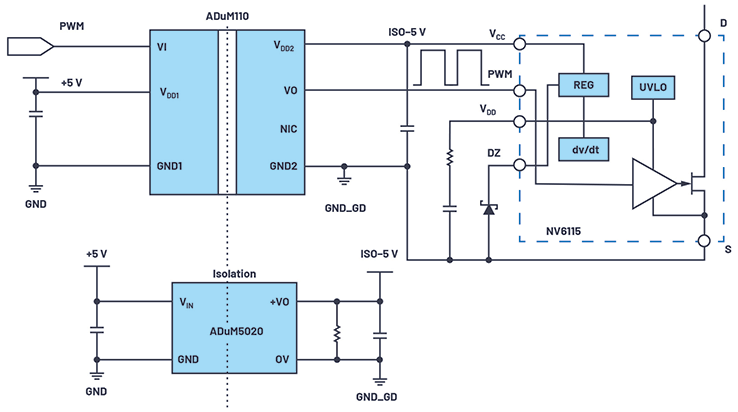

Presently, GaN devices are typically packaged separately from their driver. This is due to the differences in the manufacturing processes of GaN switches and isolation drivers. In the future, integrating the GaN transistors and the isolation barrier drivers into the same package will further enhance the switching performance as it will reduce the inductor parasitics. Some key telecom vendors plan to package their GaN systems as individual customized modules themselves. In the long term, the driver for GaN systems may enable its implementation into smaller size isolator modules. Tiny, single-channel examples such as the ADuM110N (low propagation delay, high frequency) and the isoPower ADuM5020, which offer simplicity in design, as shown in Figure 4, to support this trend.

Figure 3. A single-channel, isolated isoCoupler driver application overview for a GaN transistor.

New Trend: Customized, Isolated GaN Modules

Presently, GaN devices are typically packaged separately from their driver. This is due to the differences in the manufacturing processes of GaN switches and isolation drivers. In the future, integrating the GaN transistors and the isolation barrier drivers into the same package will further enhance the switching performance as it will reduce the inductor parasitics. Some key telecom vendors plan to package their GaN systems as individual customized modules themselves. In the long term, the driver for GaN systems may enable its implementation into smaller size isolator modules. Tiny, single-channel examples such as the ADuM110N (low propagation delay, high frequency) and the isoPower ADuM5020, which offer simplicity in design, as shown in Figure 4, to support this trend.

Figure 4. The iCoupler ADuM110N and the isoPower ADuM5020 are good matches for the Navitas GaN module.

Conclusion

GaN transistors with smaller device sizes, lower on resistance, and higher working frequency offer many advantages over traditional silicon-based MOSFETs. Adopting GaN technology could cut total solution size without compromising efficiency. GaN devices have great prospects, especially in medium and high voltage power supplies. ADI’s iCoupler® technology brings excellent benefits in driving the emerging GaN switches and transistors.

[b]References[/b]

Figure 4. The iCoupler ADuM110N and the isoPower ADuM5020 are good matches for the Navitas GaN module.

Conclusion

GaN transistors with smaller device sizes, lower on resistance, and higher working frequency offer many advantages over traditional silicon-based MOSFETs. Adopting GaN technology could cut total solution size without compromising efficiency. GaN devices have great prospects, especially in medium and high voltage power supplies. ADI’s iCoupler® technology brings excellent benefits in driving the emerging GaN switches and transistors.

[b]References[/b]

- Lower gate capacitance and output capacitance.

- Lower drain-source on resistor (RDS(ON)) for higher current operation, resulting in lower conduction losses.

- Low or zero reverse-recovery charge (QRR), as there is no need for a body diode.

Figure 1. Typical ac/dc power supply for telecom and server applications.

Typical Isolation Solutions and Requirements

UART Communication Isolation

The change from a previous analog controlled system to a DSP controlled system requires the isolation of the pulse-width modulated (PWM) signals and the additional control signals. The dual-channel ADuM121 can be used for UART communication between DSPs. To minimize the total system size required for the isolation, the epoxy resin sealant is used in board assembly. Smaller size and high power density are critical in the evolution of ac/dc. Smaller package isolators are required.

PFC Section Isolation

The propagation delay/skew, negative bias/clamp, and size of the ISO gate driver is critical for GaN in contrast to MOS. To drive a half-bridge or full-bridge transistor with GaN, the ADuM3123 single-channel driver can be used for the PFC section and the ADuM4223 dual-channel driver for the LLC section.

Powering the Devices Behind the Isolation Barrier

Based on ADI’s isoPower® technology, which is designed for power transfer across the isolation barrier, the ADuM5020 is a compact chip solution that can match a GaN transistor’s auxiliary power supply with that of a gate.

Isolation Requirements

Table 1. Comparison of Different Methods in Driving a GaN Half-Bridge Transistor

Figure 1. Typical ac/dc power supply for telecom and server applications.

Typical Isolation Solutions and Requirements

UART Communication Isolation

The change from a previous analog controlled system to a DSP controlled system requires the isolation of the pulse-width modulated (PWM) signals and the additional control signals. The dual-channel ADuM121 can be used for UART communication between DSPs. To minimize the total system size required for the isolation, the epoxy resin sealant is used in board assembly. Smaller size and high power density are critical in the evolution of ac/dc. Smaller package isolators are required.

PFC Section Isolation

The propagation delay/skew, negative bias/clamp, and size of the ISO gate driver is critical for GaN in contrast to MOS. To drive a half-bridge or full-bridge transistor with GaN, the ADuM3123 single-channel driver can be used for the PFC section and the ADuM4223 dual-channel driver for the LLC section.

Powering the Devices Behind the Isolation Barrier

Based on ADI’s isoPower® technology, which is designed for power transfer across the isolation barrier, the ADuM5020 is a compact chip solution that can match a GaN transistor’s auxiliary power supply with that of a gate.

Isolation Requirements

Table 1. Comparison of Different Methods in Driving a GaN Half-Bridge Transistor

| Solution | Technology | Merits | Challenge | ADI product |

| Integrated high-side and low-side driver | Level shift | Simplest single-chip solution | Large delay time, limited CMTI, external bootstrap circuit | |

| Dual-isolated Integrated driver | Magnetic | Single-chip solution | Sacrifice layout flexibility, need time to charge the bootstrap cap | ADuM4223 |

| Single-channel isolated driver | Magnetic | Easy for layout, high CMTI, low propagation delay/skew | Require external auxiliary power supply | ADuM3123, ADuM4121 |

| Isolators and ISO power | Magnetic | Layout flexibility, easy for negative bias, no bootstrap circuit | High cost, EMI issue | ADuM110+, ADuM5020 |

- Maximum allowable gate voltage <7 V

- >100 kV/ms dv/dt at switching node, 100 kV/µs to 200 kV/µs CMTI

- High-low switch delay match ≤50 ns for 650 V application

- Negative voltage clamp (–3 V) for turning off

Figure 2. Typical ISO opportunity and requirement showing the UART isolation and PFC section isolation in isoPower devices.

Single-channel drivers are ready for GaN transistors. A typical single-channel driver is the ADuM3123, using external power supplied by Zener diodes and discrete circuits for negative bias (optional) as shown in Figure 3.

Figure 2. Typical ISO opportunity and requirement showing the UART isolation and PFC section isolation in isoPower devices.

Single-channel drivers are ready for GaN transistors. A typical single-channel driver is the ADuM3123, using external power supplied by Zener diodes and discrete circuits for negative bias (optional) as shown in Figure 3.

Figure 3. A single-channel, isolated isoCoupler driver application overview for a GaN transistor.

New Trend: Customized, Isolated GaN Modules

Presently, GaN devices are typically packaged separately from their driver. This is due to the differences in the manufacturing processes of GaN switches and isolation drivers. In the future, integrating the GaN transistors and the isolation barrier drivers into the same package will further enhance the switching performance as it will reduce the inductor parasitics. Some key telecom vendors plan to package their GaN systems as individual customized modules themselves. In the long term, the driver for GaN systems may enable its implementation into smaller size isolator modules. Tiny, single-channel examples such as the ADuM110N (low propagation delay, high frequency) and the isoPower ADuM5020, which offer simplicity in design, as shown in Figure 4, to support this trend.

Figure 3. A single-channel, isolated isoCoupler driver application overview for a GaN transistor.

New Trend: Customized, Isolated GaN Modules

Presently, GaN devices are typically packaged separately from their driver. This is due to the differences in the manufacturing processes of GaN switches and isolation drivers. In the future, integrating the GaN transistors and the isolation barrier drivers into the same package will further enhance the switching performance as it will reduce the inductor parasitics. Some key telecom vendors plan to package their GaN systems as individual customized modules themselves. In the long term, the driver for GaN systems may enable its implementation into smaller size isolator modules. Tiny, single-channel examples such as the ADuM110N (low propagation delay, high frequency) and the isoPower ADuM5020, which offer simplicity in design, as shown in Figure 4, to support this trend.

Figure 4. The iCoupler ADuM110N and the isoPower ADuM5020 are good matches for the Navitas GaN module.

Conclusion

GaN transistors with smaller device sizes, lower on resistance, and higher working frequency offer many advantages over traditional silicon-based MOSFETs. Adopting GaN technology could cut total solution size without compromising efficiency. GaN devices have great prospects, especially in medium and high voltage power supplies. ADI’s iCoupler® technology brings excellent benefits in driving the emerging GaN switches and transistors.

[b]References[/b]

Figure 4. The iCoupler ADuM110N and the isoPower ADuM5020 are good matches for the Navitas GaN module.

Conclusion

GaN transistors with smaller device sizes, lower on resistance, and higher working frequency offer many advantages over traditional silicon-based MOSFETs. Adopting GaN technology could cut total solution size without compromising efficiency. GaN devices have great prospects, especially in medium and high voltage power supplies. ADI’s iCoupler® technology brings excellent benefits in driving the emerging GaN switches and transistors.

[b]References[/b]

- Bismuth, Alain. “The Coming Hardware Revolution in Data Center Energy Efficiency.” GaN Systems, Inc., April 2020.

- “EiceDRIVER 1EDF5673K and 1EDS5663H.” Infineon Technologies AG, May 2018.

- “GN001 Application Brief: How to Drive GaN Enhancement Mode HEMT.” GaN Systems, Inc., April 2016.

- Oliver, Stephen. “GaN Power ICs: Integration Drives Performance.” Bodo’s Power Conference, Munich. Navitas, December 2017.