© Mitsubishi Electric

Components |

Mitsubishi Electric tries to solve the issue of corrosion

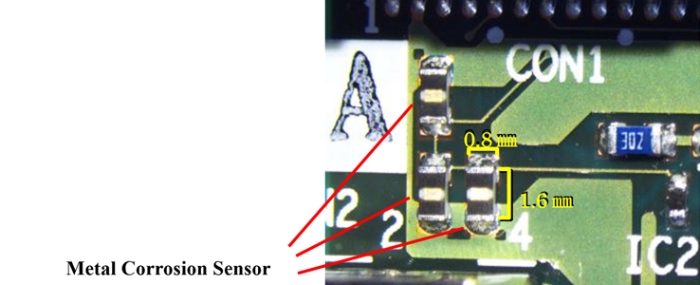

Mitsubishi Electric Corporation says it has developed what is believed to be the world's first compact metal corrosion sensor small enough to be mounted on printed circuit boards.

The new sensor utilises metal corrosion monitoring technology developed by Mitsubishi Electric that detects the degree of corrosion of metal components caused by corrosive gases such as sulfur compounds in the atmosphere. The deployment of multiple sensors with different levels of corrosion resistance allows the degree of corrosion to be detected in stages, which then would help to prevent equipment failure.

When metals are exposed to corrosive gases in the atmosphere, corrosion progresses from the surface to the inside and turns into rust. Since the electrical resistance of rust is tens of thousands of times higher than that of metal, the progress of any corrosion can be gauged by measuring the increase in electrical resistance.