© Daimler

Business |

Daimler, Sila Nano team up on next-gen battery materials

Daimler AG has acquired a minority equity stake in U.S. battery material specialist Sila Nanotechnologies Inc. (Sila Nano) as part of its research and development activities. Included in the equity stake for Daimler is a seat in the board of directors of Sila Nano.

The investment forms part of the latest round of financing, which was led by Daimler, according to a Daimler press release.

“We are on our way to a carbon-free future mobility. While our all-new EQC model enters the markets this year we are already preparing the way for the next generation of powerful battery electric vehicles. Lithium-ion technology is currently the most efficient battery technology available, and still shows plenty of potential for the future. The advancements Sila Nano have made in battery performance are very promising. We are looking forward to a fruitful cooperation, pooling our know-how on further development and fast commercialization,” said Sajjad Khan, executive VP for Connected, Autonomous, Shared & Electric Mobility, Daimler AG.

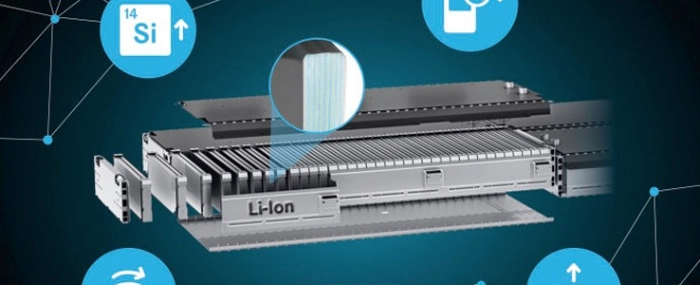

Founded in 2011 in Alameda, California, Sila Nano is a leading developer of new battery materials, which outperform existing lithium-ion technologies. The company is pursuing the potential of silicon to enable safe, scalable, high-energy density batteries, for electrification of products ranging from consumer devices to electric vehicles.

Sila Nano Co-founder and CEO Gene Berdichevsky said, “This breakthrough chemistry demonstrates up to 20% improvement today, with the potential to reach further improvements over state-of-the-art traditional Li-ion. We’re excited to be working with Daimler to bring better, more energy-dense batteries to their fleet and bring our shared vision for the future of electric vehicles to life for more people.”

Sila Nano replaces conventional graphite electrodes entirely with its proprietary silicon-dominant composite materials that enable high energy density and high cycle life, which translates to more powerful, longer-range and enduring sources of power for electric vehicles. These materials easily drop into existing Li-ion factories, making it possible to deploy efficiently and at scale.