© Analog Devices

Application Notes |

Q&A on Wireless Charging

The primary goal in any wireless power design is to guarantee delivery of the required power under worst-case power transfer conditions. However, it is equally important to avoid thermal and electrical overstress in the receiver during best-case conditions.

This is a product release announcement by Analog Devices Inc.. The issuer is solely responsible for its content.

Question 1: How is wireless charging technology is evolving?

The primary goal in any wireless power design is to guarantee delivery of the required power under worst-case power transfer conditions. However, it is equally important to avoid thermal and electrical overstress in the receiver during best-case conditions. This is especially important when output power requirements are low. For example, when the battery is fully charged or nearly fully charged and the coils are near each other. In such scenarios, available power from the wireless system is high, but demanded power is low. This excess power typically leads to high rectified voltages or a need to dissipate the excess power as heat.

There are several ways to deal with excess power capacity when the demanded receiver power is low. The rectified voltage can be clamped with a power zener diode or transient voltage suppressor. However, this solution is typically large and generates considerable heat. The transmitter power can be reduced, but this will either limit the available received power or it will reduce the transmit distance. It is also possible to communicate received power back to the transmitter and adjust transmit power accordingly. This is the technique used by wireless power standards such as the Wireless Power Consortium Qi standard. However, it is also possible to solve this issue in a compact and efficient manner without resorting to complicated digital communication techniques. Communications techniques that communicate via small variations in the transmitted power level require a minimum amount of power transmission and may not work for systems with variable transmit distances.

Question 2: Which are the major applications using wireless charging technology?

Lots of products use a battery as their primary power source. However, there are plenty of less glamorous products that serve equally deserving applications that also use batteries. Commonplace examples include: portable medical devices, industrial sensors and even rotating or moving equipment. However, unlike the benign consumer environment, these applications have more stringent requirements, such as the need for sterilization and even the potentially explosive surroundings like those commonly found in oil refineries and chemical processing facilities.

In many of these applications, a connector for charging purposes is difficult or impossible to use. For example, some products require sealed enclosures to protect sensitive electronics from harsh environments. Other products may simply be too small to include a connector, and in products where the battery-powered application includes movement or rotation, then it is virtually impossible to have charging with wires.

As a result, wireless charging is being adopted as an alternative method for charging batteries since this type of solution adds value, reliability and robustness in these applications where connectors cannot.

Of course, wireless charging has be commonly used in many handheld products for many years. These include cell phones, portable GPS systems and even hearing aids. On a larger scale, wireless charging has been adopted by the automotive industry for the charging of large banks of batteries commonly used in all-electric and/or hybrid-electric vehicles. A good example of this is BMW’s inductive wireless charging system for its BMWi8 automobile.

Question 3: Can you elaborate the role of semiconductor technology in bringing wireless charging solutions?

In a circuit with alternating current there exists a time-varying magnetic field in the vicinity of the wire, and if a conductor is placed into this time-varying field a current is induced.

One common occurrence in electronic systems is electrical transients, such as lightning strikes from an external source or capacitor discharge, which could be an internal repetitive disturbance, such as in the condenser discharge of an ignition system.

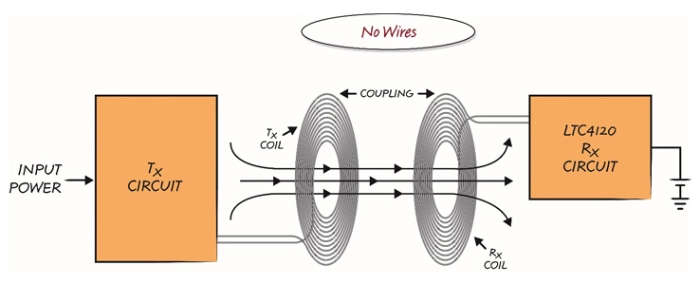

The magnetic field intensity is proportional to the magnitude of the current flowing in the conductor. Energy is transferred from a conductor that produces the fields (the primary) to any conductor on which the fields impinge (the secondary) via the magnetic coupling defined above. In a loosely coupled system, where the coupling coefficient is low, a high frequency current does not pass for long distances along a conductor but rapidly loses energy because of the impedance mismatch along the cable, which causes the energy to be reflected back to the source or radiated into the air. See the illustration above for a graphical representation of loosely coupled windings connected via a magnetic field.

When designing a wireless power charging system, a key parameter is the amount of charging power that actually adds energy to the battery. This received power depends on many factors including the amount of power being transmitted, the distance and alignment between the transmit coil and the receive coil, also known as the coupling between the coils, and finally, the tolerance of the transmit and receive components.

Question 4: What is the technology evolution and your solutions for this?

A recent product introduction to expand our offerings in the wireless battery charging arena is our LTC4123. The LTC4123 combines a 30mW wireless receiver with a constant-current/constant-voltage linear charger for NiMH batteries, such as Varta’s power one ACCU plus series. An external resonant LC tank connected to the LTC4123 enables the IC to receive power wirelessly from an alternating magnetic field generated by a transmit coil. Integrated power management circuitry converts the coupled AC current into the DC current required to charge the battery.

Wireless charging with the LTC4123 allows for a completely sealed product and eliminates the need to constantly replace primary batteries. Zn-Air (Zinc-Air) detection allows applications to work interchangeably with both rechargeable NiMH batteries and primary Zn-Air batteries with the same application circuit. Both battery types can directly power a hearing aid ASIC without the need for additional voltage conversion. By contrast, a 3.7V Li-Ion battery requires a step-down regulator in addition to the LTC4123’s functionality to power the ASIC. The LTC4123 rectifies AC power from the receive coil, and can also accept a 2.2V to 5V input to power a full-featured constant-current/constant-voltage battery charger.

Features of the charger include programmable charge current up to 25mA, a single-cell 1.5V battery charge voltage with ±0.5% accuracy, charge status indication and an onboard safety charge termination timer. A temperature-compensated charge voltage protects the NiMH battery and prevents overcharging. The LTC4123 prevents charging when batteries are inserted with reverse polarity and pauses charging if the temperature becomes too hot or too cold. The LTC4123 is housed in a highly compact, low profile (0.75mm) 6-pin 2mm x 2mm DFN package with backside metal pad for excellent thermal performance.

Question 5: Any challenges you would like to highlight?

None at this time.

.jpg)