© lockheed martin

Components |

First 3D-printed component flies on US Navy’s Trident II D5 missile

The U.S. Navy’s Fleet Ballistic Missile program has taken a step further into the future with its 3D-printed missile component.

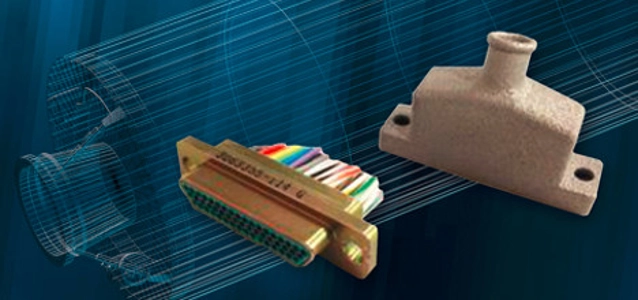

A part called a connector backshell has made its debut as part of the Navy’s test flights March 14 to 16 of three Trident II D5 Fleet Ballistic Missiles built by Lockheed Martin.

By using an entirely digital processes, Lockheed Martin engineers designed and fabricated the new component in – what the company claims to be – half the time of traditional methods. The connector backshell, which protects cable connectors in the missile, is made from an aluminum alloy and measures about an inch across.

The D5 missile has achieved a total of 160 successful test flights since design completion in 1989. In the most recent tests, the Navy launched the unarmed missiles in the Atlantic Ocean from a submerged submarine. The missiles were converted into test configurations using kits produced by Lockheed Martin that contain range safety devices and flight telemetry instrumentation. The test flights were part of a Follow-on Commander’s Evaluation Test of the Trident Strategic Weapon System conducted under the testing guidelines of the Joint Chiefs of Staff.

“These tests demonstrate the readiness and reliability of this crucial system that protects what matters most for the nation,” said Eric Scherff, vice president of Fleet Ballistic Missile programs, Lockheed Martin Space Systems. “The Trident Strategic Weapon System stands guard every minute of every day, thanks to the dedication and forward thinking of the Navy program office, the submarine crews and the industry team.”