© linear technology

Application Notes |

To boldly deliver what no linear charger has done before …

Switch mode battery chargers are popular choices in applications due to their topology flexibility, multi-chemistry charging, high charging efficiencies which minimize heat to enable fast charge times and wide operating voltage ranges.

Background

Nevertheless, some downsides of switching chargers include relatively high cost, more complicated inductor-based designs, potential noise generation and larger footprint solutions. On the other hand, traditional linear topology battery chargers are often valued for their compact footprints, simplicity and lower cost. Drawbacks of traditional linear chargers have included limited input and battery voltage ranges, higher relative current consumption, excessive power dissipation, limited charge termination algorithms and lower relative efficiency (efficiency ~ [VOUT/VIN] * 100%).

Modern lead acid (LA), wireless power, energy harvesting, solar charging, remote sensor and embedded automotive applications have been traditionally powered by switchmode chargers for the positive reasons stated above; however an opportunity exists for an ultra-low consumption current, high voltage linear battery charger that negates its usually associated drawbacks.

Cutting-Edge Applications Demand More Effective Linear Chargers

Some leading edge application spaces, where innovative, high voltage and ultra-low quiescent current linear chargers can be beneficial include the following:

This regulation mechanism allows the charge current to be selected based on the battery’s requirement and the maximum power available from the charging source. The LTC4079 automatically reduces the charge current when the input source cannot provide the programmed charge current.

The LTC4079’s Differential Voltage Regulation (VIN-VBAT provides an additional method to keep the input voltage from collapsing when the input power comes from a weak power source. If the input voltage falls close to the battery voltage, the differential voltage regulation loop in LTC4079 keeps the input voltage above the battery voltage by 160mV (typical value) by reducing the charge current as the input voltage to battery differential voltage falls.

In both of the above regulation conditions, the input source must provide at least the quiescent current of the device to prevent UVLO. The charge timer is paused whenever the charge current is reduced due to input voltage regulation or differential voltage regulation conditions.

Nickel Charging

The LTC4079’s design can also handle Nickel batteries. For nickel-chemistry batteries (e.g. Nickel Cadmium [NiCd] and Nickel metal hydride [NiMH]), the possibility of overcharging must be considered. A typical method is to trickle charge with low currents for a long period of time. Since NiCd and NiMH batteries can absorb a C/300 charge rate indefinitely, shorter duration charging is possible using a timed charge algorithm.

It is advisable to charge the battery to no more than 125% of its capacity. For example, a 1000mAh NiMH battery can be charged at a 100mA charge current setting for 12-14 hours. The constant voltage regulation safely tapers the charge current to near zero once the battery reaches its full capacity.

Conclusion

The LTC4079 delivers what no linear battery charger has done before. The device’s wide input voltage and charge voltage range, multi-chemistry operation, solar capability, ultra-low quiescent current both while charging & upon termination, simple solution and compact footprint enable it to achieve high performance in leading-edge applications where only more complicated switching regulator-based topologies were once the only option.

-----

Author: By Steve Knoth, Senior Product Marketing Engineer, Power Products, © Linear Technology Corporation

This regulation mechanism allows the charge current to be selected based on the battery’s requirement and the maximum power available from the charging source. The LTC4079 automatically reduces the charge current when the input source cannot provide the programmed charge current.

The LTC4079’s Differential Voltage Regulation (VIN-VBAT provides an additional method to keep the input voltage from collapsing when the input power comes from a weak power source. If the input voltage falls close to the battery voltage, the differential voltage regulation loop in LTC4079 keeps the input voltage above the battery voltage by 160mV (typical value) by reducing the charge current as the input voltage to battery differential voltage falls.

In both of the above regulation conditions, the input source must provide at least the quiescent current of the device to prevent UVLO. The charge timer is paused whenever the charge current is reduced due to input voltage regulation or differential voltage regulation conditions.

Nickel Charging

The LTC4079’s design can also handle Nickel batteries. For nickel-chemistry batteries (e.g. Nickel Cadmium [NiCd] and Nickel metal hydride [NiMH]), the possibility of overcharging must be considered. A typical method is to trickle charge with low currents for a long period of time. Since NiCd and NiMH batteries can absorb a C/300 charge rate indefinitely, shorter duration charging is possible using a timed charge algorithm.

It is advisable to charge the battery to no more than 125% of its capacity. For example, a 1000mAh NiMH battery can be charged at a 100mA charge current setting for 12-14 hours. The constant voltage regulation safely tapers the charge current to near zero once the battery reaches its full capacity.

Conclusion

The LTC4079 delivers what no linear battery charger has done before. The device’s wide input voltage and charge voltage range, multi-chemistry operation, solar capability, ultra-low quiescent current both while charging & upon termination, simple solution and compact footprint enable it to achieve high performance in leading-edge applications where only more complicated switching regulator-based topologies were once the only option.

-----

Author: By Steve Knoth, Senior Product Marketing Engineer, Power Products, © Linear Technology Corporation

- Sealed lead acid (SLA) applications with low charge current. Many remote sensor / control applications benefit from the wide temperature range of an SLA battery. These remote applications are usually very low power and don’t need to charge quickly, therefore low charge currents can be used – they just need to keep the battery topped off.

- For wireless power, charging is done at very low power levels, typically less than 100mW.

- In energy harvesting applications with any micro-powered source, low quiescent current is essential to avoid competing with the downstream load current demands.

- Solar charging has voltages, both from the panel and the battery, that vary widely. For low power applications a linear charger works well.

- Remote sensors for monitoring or control, typically found in low power industrial applications, have batteries used primarily for backup. As a result, charge time is rarely important and input / battery voltages vary widely depending on the specific application. A low IQ linear charger would charger fits well here.

- Embedded automotive applications have input voltages >30V, with some even higher. For example, consider GPS location systems used as anti-theft deterrents; a linear charger with the typical 12V to 2-in-series Li-Ion (7.4V typical) with added protection to much higher voltages would be valuable for these applications.

- Low quiescent current - more energy is transferred from weak / intermittent input sources to the battery, reducing power dissipation. Further, low battery IQ also extends the lifetime of the battery when charging has terminated and when an input is not present.

- Wide input voltage range to accommodate a variety of power sources

- Wide battery charge voltage range to address multiple battery stacks

- Ability to charge multiple battery chemistries (Lithium, lead acid, Nickel)

- Simple and autonomous operation with onboard charge termination (no µC needed)

- Input voltage regulation for solar input sources

- Small and low profile solution footprints

- Advanced packaging for improved thermal performance and space efficiency

The LTC4079’s thermal regulation feature ensures maximum charge current up to the specified limit without the risk of overheating. Charging can be terminated via C/10 or an onboard adjustable timer. Other features include NTC thermistor temperature-qualified charging, bad battery detection, automatic recharge with sampled feedback in standby for negligible battery drain and an open-drain CHRG pin status output. Once the battery is charged, the battery voltage is sampled via a feedback network every 3 seconds to minimize battery drain, thus prolonging battery run time. Figure 2 shows the LTC4079’s typical full Li-Ion charge cycle, with C/10 charge termination. The LTC4079 is housed in a low profile (0.75mm) 10-pin 3mm x 3mm DFN package with backside metal pad for excellent thermal performance. The device is guaranteed for operation from –40°C to 125°C. Its key features are:Figure 1. LTC4079 Typical Application Circuit for Charging a 7.4V Li-Ion Battery -----

Figure 2. LTC4079 Li-Ion Charge Cycle -----

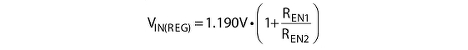

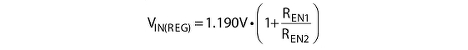

Figure 3. Setting LTC4079’s Input Voltage Regulation ----- All images have zoom.

- Wide Input Voltage Range: 2.7V to 60V

- Adjustable Battery Voltage: 1.2V to 60V

- Adjustable Charge Current: 10mA to 250mA

- Low Quiescent Current While Charging: IIN = 4µA

- Ultralow Battery Drain When Shutdown or Charged: IBAT < 0.01µA

- Auto Recharge

- Input Voltage Regulation for High Impedance Sources

- Thermal Regulation Maximizes Output Current without Overheating

- Constant Voltage Feedback with ±0.5% Accuracy

- NTC Thermistor Input for Temperature Qualified Charging

- Adjustable Safety Timer

- Charging Status Indication

- Thermally Enhanced 10-Lead (3mm × 3mm) DFN Package

This regulation mechanism allows the charge current to be selected based on the battery’s requirement and the maximum power available from the charging source. The LTC4079 automatically reduces the charge current when the input source cannot provide the programmed charge current.

The LTC4079’s Differential Voltage Regulation (VIN-VBAT provides an additional method to keep the input voltage from collapsing when the input power comes from a weak power source. If the input voltage falls close to the battery voltage, the differential voltage regulation loop in LTC4079 keeps the input voltage above the battery voltage by 160mV (typical value) by reducing the charge current as the input voltage to battery differential voltage falls.

In both of the above regulation conditions, the input source must provide at least the quiescent current of the device to prevent UVLO. The charge timer is paused whenever the charge current is reduced due to input voltage regulation or differential voltage regulation conditions.

Nickel Charging

The LTC4079’s design can also handle Nickel batteries. For nickel-chemistry batteries (e.g. Nickel Cadmium [NiCd] and Nickel metal hydride [NiMH]), the possibility of overcharging must be considered. A typical method is to trickle charge with low currents for a long period of time. Since NiCd and NiMH batteries can absorb a C/300 charge rate indefinitely, shorter duration charging is possible using a timed charge algorithm.

It is advisable to charge the battery to no more than 125% of its capacity. For example, a 1000mAh NiMH battery can be charged at a 100mA charge current setting for 12-14 hours. The constant voltage regulation safely tapers the charge current to near zero once the battery reaches its full capacity.

Conclusion

The LTC4079 delivers what no linear battery charger has done before. The device’s wide input voltage and charge voltage range, multi-chemistry operation, solar capability, ultra-low quiescent current both while charging & upon termination, simple solution and compact footprint enable it to achieve high performance in leading-edge applications where only more complicated switching regulator-based topologies were once the only option.

-----

Author: By Steve Knoth, Senior Product Marketing Engineer, Power Products, © Linear Technology Corporation

This regulation mechanism allows the charge current to be selected based on the battery’s requirement and the maximum power available from the charging source. The LTC4079 automatically reduces the charge current when the input source cannot provide the programmed charge current.

The LTC4079’s Differential Voltage Regulation (VIN-VBAT provides an additional method to keep the input voltage from collapsing when the input power comes from a weak power source. If the input voltage falls close to the battery voltage, the differential voltage regulation loop in LTC4079 keeps the input voltage above the battery voltage by 160mV (typical value) by reducing the charge current as the input voltage to battery differential voltage falls.

In both of the above regulation conditions, the input source must provide at least the quiescent current of the device to prevent UVLO. The charge timer is paused whenever the charge current is reduced due to input voltage regulation or differential voltage regulation conditions.

Nickel Charging

The LTC4079’s design can also handle Nickel batteries. For nickel-chemistry batteries (e.g. Nickel Cadmium [NiCd] and Nickel metal hydride [NiMH]), the possibility of overcharging must be considered. A typical method is to trickle charge with low currents for a long period of time. Since NiCd and NiMH batteries can absorb a C/300 charge rate indefinitely, shorter duration charging is possible using a timed charge algorithm.

It is advisable to charge the battery to no more than 125% of its capacity. For example, a 1000mAh NiMH battery can be charged at a 100mA charge current setting for 12-14 hours. The constant voltage regulation safely tapers the charge current to near zero once the battery reaches its full capacity.

Conclusion

The LTC4079 delivers what no linear battery charger has done before. The device’s wide input voltage and charge voltage range, multi-chemistry operation, solar capability, ultra-low quiescent current both while charging & upon termination, simple solution and compact footprint enable it to achieve high performance in leading-edge applications where only more complicated switching regulator-based topologies were once the only option.

-----

Author: By Steve Knoth, Senior Product Marketing Engineer, Power Products, © Linear Technology Corporation