© Analog Devices

Application Notes |

Model-based design of advanced motor control systems

Leveraging advanced processor functionality to facilitate ease of design has been discussed throughout recent decades. An application note, written by Anders Frederiksen.

[chapter-index=Application Note link-to=32902,32903,32904]Chapter Index[/chapter-index]Nowadays even greater design flexibility allows engineers to use standard Model-Based design with MATLAB® and Simulink® can be used to optimize motor control systems functionality and to minimize overall design time. It also enables design engineers to reuse simulation models to ensure the correct functionality and desired performance of a system in its end market application.

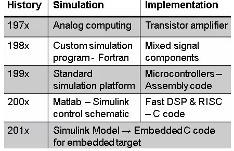

Model-Based Design (MBD) has been a discussion topic for decades but has only in recent years evolved into a complete design flow - from model creation to complete implementation. In the 1970s analog computing platforms were available for simulation but control hardware implementation was done at the transistor level.

Simulation tools advances though to the 2000s saw the introduction of graphical control schematic entry tools and control design tools that vastly simplified the task of complex control design and evaluation. However, the control system designer still developed the hardware control algorithm by writing C code to mirror the simulated design. Now at the start of this decade, complete MBD allows a common control design for both simulation and hardware implementation platforms enabling complex control algorithms to be rapidly deployed on hardware platforms. MBD is a process that uses a system model as an executable specification throughout development. This simulation-based approach gives you a better understanding of design alternatives and trade-offs than traditional hardware prototype-based design methodologies, enabling you to optimize your design to meet predefined performance criteria.

Rather than using complex structures and extensive software code, designers can define models with advanced functional characteristics using continuous-time and discrete-time building blocks. Existing C code can be integrated with standard control library blocks to maximize design efficiency. These models, used with simulation tools, can lead to rapid prototyping, software testing and hardware-in-the-loop (HIL) simulation. Simulation enables specification discrepancies and modeling errors to be found immediately, rather than later in the design cycle. Automatic code generation eliminates the manual steps in implementation the same algorithm to run on the hardware platform. This simplifies the design process, minimizes errors in hardware design implementation and reduces the overall time-to-market.All image © Analog Devices.