© Linear Technology

Application Notes |

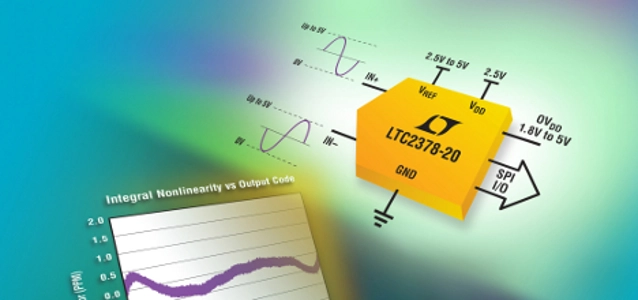

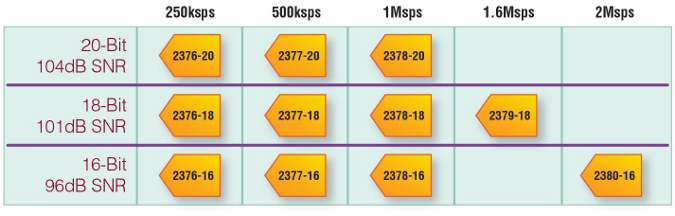

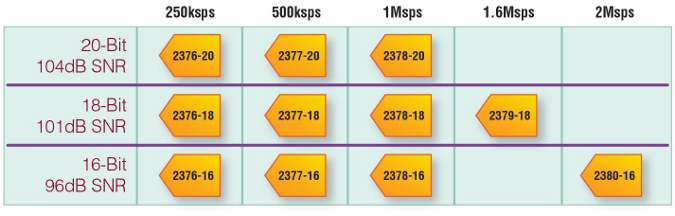

[chapter-index=Index Head link-to=24934,24935,24936]Here you find links to the other parts of the application note.[/chapter-index]In each case, these systems push the boundaries of state-of-the-art signal processing and require parts-per-million (ppm) accuracy. The design of such systems is highly sophisticated, incorporating wide-dynamic-range sensors, high-order control loops, and the highest performance integrated circuit components. At the core of many precision industrial systems is an analog-to-digital converter (ADC). The ADC plays a pivotal role, translating signals from the analog domain to digital for digital signal processing. The accuracy and performance of the ADC often defines the accuracy and performance of the overall system. This article discusses how breakthrough data conversion performance enables a new generation of higher-accuracy lower-cost industrial systems. Precision Industrial System Requirements Precision industrial systems require high-resolution ADCs to digitize real-world analog signals. Excellent DC specifications (such as offset, gain, and linearity) are typically required for the analog signal chain, including the ADC and supporting signal-conditioning circuitry (such as amplifiers, filters, and references). In order to achieve ppm-level resolution and accuracy, many precision industrial systems are digitally calibrated to null out any system-level offset and gain errors. As a result, system accuracy is often limited by errors that cannot be suppressed by infrequent calibration, and system designers may be more concerned with potential drift of key parameters than they are with their static values. For example, precision systems may require not only ppm-level accuracy at a fixed temperature, but also sub-ppm/C drift accuracy over a wide operating temperature range. ADC linearity is of critical concern for overall system accuracy. ADC linearity is determined by complex interactions between the analog input signal and the ADC’s internal design and architecture. ADC nonlinearity errors are extremely difficult to calibrate at the system level, since such errors vary substantially from one digital code to another, and because they may be a strong function of temperature. ADC linearity and stability over temperature are crucial for the overall accuracy of precision systems. Breakthrough Performance To meet these design challenges, a new family of 20-bit SAR ADCs provides an unprecedented level of performance and accuracy, simplifying the design of high-precision industrial systems. The LTC2378-20 is the flagship product in a family of pin- and software-compatible SAR ADCs featuring up to 20-bit no-missing-codes resolution and up to 104dB SNR at sample rates from 250ksps to 2Msps. The DC precision of the LTC2378-20 is particularly impressive: the ADC integral nonlinearity (INL) errors are typically less than 0.5ppm, and are guaranteed to be less than 2ppm, for all codes over the entire operating temperature range from -40°C to +85°C. The offset error is 13ppm (maximum) with 0.007ppm/°C drift, and the gain error is 10ppm with 0.05ppm/°C drift. This extreme level of performance is achieved while operating at very low power, from 5.3mW at 250Ksps to 21mW at 1Msps. Each device is available in small MSOP-16 and DFN-16 packages. Figure 1 summarizes the new ADC family.

Characteristics of SAR ADCs

SAR ADCs are characterized by their ability to acquire a precise snapshot in time of an analog input signal and to complete an analog-to-digital conversion operation within a single clock cycle. SAR ADCs excel at asynchronous “start-and-go” operations, and they are easy to use because the conversion result is available immediately within the same clock cycle.

The ability to produce accurate conversion results with no cycle latency, even after long idle periods, makes SAR ADCs ideal for many precision applications, including sensors, control loops, data acquisition, and automated test equipment. Other types of ADCs, such as delta-sigma and pipelined ADCs require multiple clock cycles to complete a single conversion.

Circuit Architecture

The guaranteed ppm-level linearity and accuracy of LTC2378-20 is a game changer for many precision industrial systems. LTC2378-20 has been designed using a proprietary architecture that ensures linearity and minimizes its sensitivity to changes in temperature and other operating conditions. As a result, an unprecedented 2ppm INL specification is guaranteed over the entire operating temperature range.

The SAR ADC algorithm is based on a binary-search principle. The analog input is sampled onto a capacitor and is compared sequentially to fractions of a reference voltage selected by the SAR algorithm. The SAR ADC comprises three critical components: a capacitor-based digital-to-analog converter (CDAC), a fast low-noise comparator circuit, and a successive-approximation register.

The INL performance of a conventional SAR ADC may be limited by finite matching accuracy of individual capacitors in the CDAC, and many precision SAR ADCs employ analog or digital trimming techniques to improve the matching accuracy. However, as temperature varies and package and board stress is applied, CDAC capacitor matching invariably degrades and may limit the ADC’s linearity.

Each device is available in small MSOP-16 and DFN-16 packages. Figure 1 summarizes the new ADC family.

Characteristics of SAR ADCs

SAR ADCs are characterized by their ability to acquire a precise snapshot in time of an analog input signal and to complete an analog-to-digital conversion operation within a single clock cycle. SAR ADCs excel at asynchronous “start-and-go” operations, and they are easy to use because the conversion result is available immediately within the same clock cycle.

The ability to produce accurate conversion results with no cycle latency, even after long idle periods, makes SAR ADCs ideal for many precision applications, including sensors, control loops, data acquisition, and automated test equipment. Other types of ADCs, such as delta-sigma and pipelined ADCs require multiple clock cycles to complete a single conversion.

Circuit Architecture

The guaranteed ppm-level linearity and accuracy of LTC2378-20 is a game changer for many precision industrial systems. LTC2378-20 has been designed using a proprietary architecture that ensures linearity and minimizes its sensitivity to changes in temperature and other operating conditions. As a result, an unprecedented 2ppm INL specification is guaranteed over the entire operating temperature range.

The SAR ADC algorithm is based on a binary-search principle. The analog input is sampled onto a capacitor and is compared sequentially to fractions of a reference voltage selected by the SAR algorithm. The SAR ADC comprises three critical components: a capacitor-based digital-to-analog converter (CDAC), a fast low-noise comparator circuit, and a successive-approximation register.

The INL performance of a conventional SAR ADC may be limited by finite matching accuracy of individual capacitors in the CDAC, and many precision SAR ADCs employ analog or digital trimming techniques to improve the matching accuracy. However, as temperature varies and package and board stress is applied, CDAC capacitor matching invariably degrades and may limit the ADC’s linearity.

Precision Industrial Systems demand new level of data conversion accuracy

Many industrial systems require measurement of critical parameters with extreme accuracy. Examples include seismic monitoring, energy exploration, airflow sensing, and silicon wafer fabrication.

[chapter-index=Index Head link-to=24934,24935,24936]Here you find links to the other parts of the application note.[/chapter-index]In each case, these systems push the boundaries of state-of-the-art signal processing and require parts-per-million (ppm) accuracy. The design of such systems is highly sophisticated, incorporating wide-dynamic-range sensors, high-order control loops, and the highest performance integrated circuit components. At the core of many precision industrial systems is an analog-to-digital converter (ADC). The ADC plays a pivotal role, translating signals from the analog domain to digital for digital signal processing. The accuracy and performance of the ADC often defines the accuracy and performance of the overall system. This article discusses how breakthrough data conversion performance enables a new generation of higher-accuracy lower-cost industrial systems. Precision Industrial System Requirements Precision industrial systems require high-resolution ADCs to digitize real-world analog signals. Excellent DC specifications (such as offset, gain, and linearity) are typically required for the analog signal chain, including the ADC and supporting signal-conditioning circuitry (such as amplifiers, filters, and references). In order to achieve ppm-level resolution and accuracy, many precision industrial systems are digitally calibrated to null out any system-level offset and gain errors. As a result, system accuracy is often limited by errors that cannot be suppressed by infrequent calibration, and system designers may be more concerned with potential drift of key parameters than they are with their static values. For example, precision systems may require not only ppm-level accuracy at a fixed temperature, but also sub-ppm/C drift accuracy over a wide operating temperature range. ADC linearity is of critical concern for overall system accuracy. ADC linearity is determined by complex interactions between the analog input signal and the ADC’s internal design and architecture. ADC nonlinearity errors are extremely difficult to calibrate at the system level, since such errors vary substantially from one digital code to another, and because they may be a strong function of temperature. ADC linearity and stability over temperature are crucial for the overall accuracy of precision systems. Breakthrough Performance To meet these design challenges, a new family of 20-bit SAR ADCs provides an unprecedented level of performance and accuracy, simplifying the design of high-precision industrial systems. The LTC2378-20 is the flagship product in a family of pin- and software-compatible SAR ADCs featuring up to 20-bit no-missing-codes resolution and up to 104dB SNR at sample rates from 250ksps to 2Msps. The DC precision of the LTC2378-20 is particularly impressive: the ADC integral nonlinearity (INL) errors are typically less than 0.5ppm, and are guaranteed to be less than 2ppm, for all codes over the entire operating temperature range from -40°C to +85°C. The offset error is 13ppm (maximum) with 0.007ppm/°C drift, and the gain error is 10ppm with 0.05ppm/°C drift. This extreme level of performance is achieved while operating at very low power, from 5.3mW at 250Ksps to 21mW at 1Msps.

Each device is available in small MSOP-16 and DFN-16 packages. Figure 1 summarizes the new ADC family.

Characteristics of SAR ADCs

SAR ADCs are characterized by their ability to acquire a precise snapshot in time of an analog input signal and to complete an analog-to-digital conversion operation within a single clock cycle. SAR ADCs excel at asynchronous “start-and-go” operations, and they are easy to use because the conversion result is available immediately within the same clock cycle.

The ability to produce accurate conversion results with no cycle latency, even after long idle periods, makes SAR ADCs ideal for many precision applications, including sensors, control loops, data acquisition, and automated test equipment. Other types of ADCs, such as delta-sigma and pipelined ADCs require multiple clock cycles to complete a single conversion.

Circuit Architecture

The guaranteed ppm-level linearity and accuracy of LTC2378-20 is a game changer for many precision industrial systems. LTC2378-20 has been designed using a proprietary architecture that ensures linearity and minimizes its sensitivity to changes in temperature and other operating conditions. As a result, an unprecedented 2ppm INL specification is guaranteed over the entire operating temperature range.

The SAR ADC algorithm is based on a binary-search principle. The analog input is sampled onto a capacitor and is compared sequentially to fractions of a reference voltage selected by the SAR algorithm. The SAR ADC comprises three critical components: a capacitor-based digital-to-analog converter (CDAC), a fast low-noise comparator circuit, and a successive-approximation register.

The INL performance of a conventional SAR ADC may be limited by finite matching accuracy of individual capacitors in the CDAC, and many precision SAR ADCs employ analog or digital trimming techniques to improve the matching accuracy. However, as temperature varies and package and board stress is applied, CDAC capacitor matching invariably degrades and may limit the ADC’s linearity.

Each device is available in small MSOP-16 and DFN-16 packages. Figure 1 summarizes the new ADC family.

Characteristics of SAR ADCs

SAR ADCs are characterized by their ability to acquire a precise snapshot in time of an analog input signal and to complete an analog-to-digital conversion operation within a single clock cycle. SAR ADCs excel at asynchronous “start-and-go” operations, and they are easy to use because the conversion result is available immediately within the same clock cycle.

The ability to produce accurate conversion results with no cycle latency, even after long idle periods, makes SAR ADCs ideal for many precision applications, including sensors, control loops, data acquisition, and automated test equipment. Other types of ADCs, such as delta-sigma and pipelined ADCs require multiple clock cycles to complete a single conversion.

Circuit Architecture

The guaranteed ppm-level linearity and accuracy of LTC2378-20 is a game changer for many precision industrial systems. LTC2378-20 has been designed using a proprietary architecture that ensures linearity and minimizes its sensitivity to changes in temperature and other operating conditions. As a result, an unprecedented 2ppm INL specification is guaranteed over the entire operating temperature range.

The SAR ADC algorithm is based on a binary-search principle. The analog input is sampled onto a capacitor and is compared sequentially to fractions of a reference voltage selected by the SAR algorithm. The SAR ADC comprises three critical components: a capacitor-based digital-to-analog converter (CDAC), a fast low-noise comparator circuit, and a successive-approximation register.

The INL performance of a conventional SAR ADC may be limited by finite matching accuracy of individual capacitors in the CDAC, and many precision SAR ADCs employ analog or digital trimming techniques to improve the matching accuracy. However, as temperature varies and package and board stress is applied, CDAC capacitor matching invariably degrades and may limit the ADC’s linearity.

EDITOR'S NOTE_ Don't forget the links to part 2 and 3 of the application note. You find them in the small box at the top right corner of the article.The LTC2378-20 achieves its state-of-the-art INL performance by implementing a proprietary architecture that makes the INL independent of CDAC capacitor mismatch, thus making it exceptionally robust to the type of temperature variations and package stress effects that are present in harsh industrial environments. Furthermore, the comparator circuit is designed carefully to balance speed, power, and noise, such that the LTC2378-20 achieves an unprecedented 104dB signal-to-noise Ratio (SNR), consuming only 21mW at 1Msps without introducing any cycle latency. The power consumption of the LTC2378-20 family of SAR ADCs is proportional to the sampling rate, so that they consume only microwatts when operated at 1ksps. ----- Graphics: © Linear Technology Corporation