© pichetw dreamstime.com

Analysis |

A new semiconductor era is on the horizon

Fan-in WLP is experiencing continuous growth and attracting new applications, writes Yole Développement.

Indeed fan-in WLP technology confirms its presence on the semiconductor market with indisputable benefits linked to cost and form factor. Technology innovation continues and widens the sphere of possibilities of fan-in WLP solutions.

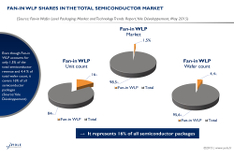

Although seemingly out of the spotlight, fan-in Wafer Level Packages (WLP) remain a highly important and constant presence with unmatchable advantages in cost and form factor. Fan-in WLP holds 16 percent of the total number of packages, while serving 4.4 percent of the wafer market at only 1.5 percent of the total semiconductor revenue.

“Fan-in WLP is forecasted to continue a stable growth, with a market of USD 5.3bn in 2014 and a CAGR between 2014 and 2020 of 7 percent”, explains Andrej Ivankovic, Technology & Market Analyst, in the Advanced Packaging and Semiconductor Manufacturing team, at Yole. And he adds: “The total wafer count in 300mm equivalent wafers is reaching 4 million with a projected CAGR of 8 percent while the unit number is found at 36 billion with a projected CAGR of 9 percent”. Throughout the past few years, MEMS and CMOS image sensors have been increasing their share compared to analog, mixed signal and digital ICs and are now accounting for more than 50 percent of the total revenue. The leading applications by wafer demand in the analog/mixed signal/digital domain are BT+WiFi+FM combos and RF transceivers followed by PMU, audio/video codecs, DC/DC converters, ESD/EMI IPD. MEMS devices are led by digital compasses, RF filters, accelerometers and gyroscopes. CMOS image sensors are strongly positioned in 2nd place by overall fan-in application rankings. “Current bump pitch in high volume is mostly at 0.4mm with 0.35mm already present as well. Particular effort is being made to increase the die size and I/O count” says Santosh Kumar, Senior Technology & Market research analyst, Advanced Packaging and Semiconductor Manufacturing at Yole. Max I/O count in high volume is heading above 200 and announcements have been made for high volume production up to 800 I/Os. The die size sweet spot ranges up to 7mmx7mm with 8mmx8mm and 9mmx9mm qualified and ready. ----- For more information, visit © Yole Développement-----

-----