© aydindurdu dreamstime.com

Application Notes |

Q&A on automotive electronics market trends

There are many applications in automotive electronic systems that require continuous power even when the car is parked, such as remote keyless entry, security and even personal infotainment systems, which usually incorporate navigation, etc.

What is the trend of the Power product in this application?

The automotive market is a focused end market for Linear Technology. This market has grown to 20% of total sales in the last fiscal year, consistently growing faster than the overall growth of the company. Much of the innovation and differentiation in the automotive industry has its origins in vehicle electronics. The need for improved safety, fuel efficiency and comfort presents significant opportunity. The proliferation of hybrid and all-electric vehicles will steadily drive the need for innovative analog products. In addition to increased vehicle electronics, the underlying world automotive market is also expected to grow steadily.

There are many applications in automotive electronic systems that require continuous power even when the car is parked, such as remote keyless entry, security and even personal infotainment systems, which usually incorporate navigation, GPS location and e-call functionality. Maybe it is hard to understand why these systems have to remain on even when the car is not moving, but the GPS aspect of this system has to be “always-on” for emergency and security purposes.

This is a necessary requirement so that rudimentary control can be employed by an external operated when needed. A key requirement for these applications is low quiescent current to extend battery life. Linear Technology has been producing switching regulators with standby quiescent current less than 5A. As a result, these products are well positioned to be adopted by auto electronics manufacturers.

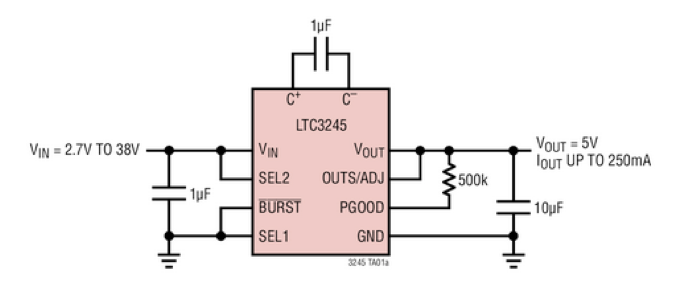

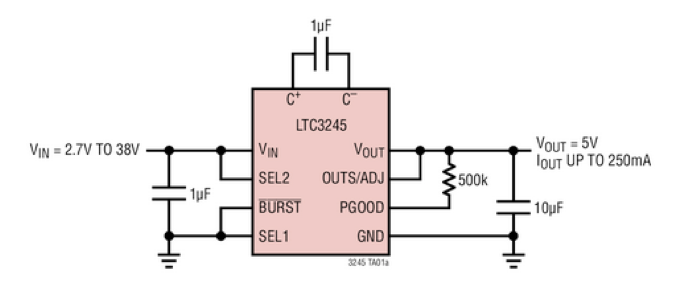

Figure 1. LTC3245 Schematic Delivering a Fixed 5V Output from a 2.7V to 38V Input

A few years ago, Linear Technology introduced our LT8614 Silent Switcher® regulator, which delivers the desired effects of a shielded box without using one, while also eliminating many of the above mentioned drawbacks. Nevertheless, in some noise applications, power supply designers simply do not like to use inductor-based regulators due to their associated EMI emissions. At the same time, the use of a linear regulator (aka LDO) may be precluded due to its relatively low conversion efficiency and need for heat sinking. As a result, they can turn to a common alternative, the charge pump. Therefore, we introduced our LTC3245 and LTC3260 to provide designers with another practical alternative solution that sits between these two afore mentioned approaches.

What are the advantages of your Power product and solution? Would you please share this innovative solution with us?

Figure 1. LTC3245 Schematic Delivering a Fixed 5V Output from a 2.7V to 38V Input

A few years ago, Linear Technology introduced our LT8614 Silent Switcher® regulator, which delivers the desired effects of a shielded box without using one, while also eliminating many of the above mentioned drawbacks. Nevertheless, in some noise applications, power supply designers simply do not like to use inductor-based regulators due to their associated EMI emissions. At the same time, the use of a linear regulator (aka LDO) may be precluded due to its relatively low conversion efficiency and need for heat sinking. As a result, they can turn to a common alternative, the charge pump. Therefore, we introduced our LTC3245 and LTC3260 to provide designers with another practical alternative solution that sits between these two afore mentioned approaches.

What are the advantages of your Power product and solution? Would you please share this innovative solution with us?

Figure 3. Radiated (a) and Conducted (b) Emissions of the LTC3245

The LTC3260 is an inverting charge pump DC/DC converter with dual low noise LDO regulator followers that can produce positive and negative supplies from a single 4.5V to 32V input power source, as illustrated in the Figure 4 complete schematic. It can switch between high efficiency Burst Mode® operation and low noise constant current frequency mode, allowing the designer to make an optimum trade-off for the application.

The LTC3260 can supply up to 100mA from the inverted input voltage at its charge pump output, VOUT. This VOUT also serves as the input supply to a negative LDO regulator, LDO-. The charge pump frequency can be adjusted between 50kHz and 500kHz with a single resistor. Each of the LTC3260’s LDOs is capable of supporting up to 50mA loads. And, each LDO has a dropout voltage of 300mV at 50mA, and an output resistor divider network allows the setting of the output voltage. When both regulators are disabled, the shutdown quiescent current is only 2µA.

Figure 3. Radiated (a) and Conducted (b) Emissions of the LTC3245

The LTC3260 is an inverting charge pump DC/DC converter with dual low noise LDO regulator followers that can produce positive and negative supplies from a single 4.5V to 32V input power source, as illustrated in the Figure 4 complete schematic. It can switch between high efficiency Burst Mode® operation and low noise constant current frequency mode, allowing the designer to make an optimum trade-off for the application.

The LTC3260 can supply up to 100mA from the inverted input voltage at its charge pump output, VOUT. This VOUT also serves as the input supply to a negative LDO regulator, LDO-. The charge pump frequency can be adjusted between 50kHz and 500kHz with a single resistor. Each of the LTC3260’s LDOs is capable of supporting up to 50mA loads. And, each LDO has a dropout voltage of 300mV at 50mA, and an output resistor divider network allows the setting of the output voltage. When both regulators are disabled, the shutdown quiescent current is only 2µA.

Figure 4. A 12V Input Supply to ±5V Outputs

Figure 4. A 12V Input Supply to ±5V Outputs

In most automotive environments, switching regulators usually replace linear regulators in areas where low heat dissipation and efficiency are valued. Moreover, the switching regulator is typically the first active component on the input power bus line, and therefore has a significant impact on the EMI performance of the entire product design. Filters are often used to reduce EMI by attenuating the strength at a certain frequency or over a range of frequencies. A portion of this energy that travels through space (radiated) is attenuated by adding metallic and magnetic shields. The part that rides on PCB traces (conducted) is tamed by adding ferrite beads and other filters. EMI cannot be eliminated but can be attenuated to a level that is acceptable by other communication, signal processing and digital components. The electronic content in vehicles will continue to grow no matter how many cars are sold each year. And the push for hybrid and all-electric vehicles is further propelling this market. With the growing popularity of using batteries for power sources there is an equal demand for maximizing their useful lifetime. Battery imbalance, a mismatch in the state of charge of the individual cells that make up a pack, is a problem in large lithium battery packs that is created by variations in the manufacturing process, operating conditions and battery aging. Imbalance can reduce a battery pack’s total capacity and potentially damage the battery pack. Imbalance prevents batteries from tracking from the charged state to the discharged state, and if not closely monitored, can cause batteries to be overcharged or over-discharged, which will permanently damage the cells. The batteries used in hybrid electric vehicle and electric vehicle battery packs are sorted by the battery manufacturer for capacity and internal resistance to reduce cell-to-cell variances in a given lot shipped to a customer. The vehicle battery packs are then built with carefully selected batteries to improve the total cell to cell matching in the pack. This should theoretically prevent large amounts of imbalance from developing in the battery pack, but despite this, the general consensus is that when building a large battery pack, both battery monitoring and battery balancing is required to maintain a high battery capacity for the lifetime of the battery pack. It is here that Linear’s new families of battery management system (BMS) products is well received and are currently one of the few BMS products in cars and busses in production and driving on the roads. What is the innovation of Power IC in this segment? Since the automotive market is a key market for Linear Technology, we have dedicated a lot of design resources to focus on developing products that address the issues outlined in question 1 above. For example, the tried and true solution to EMI issues is to use a shielding box for the complete circuit, and even then, a shield does not prevent coupling to sensitive circuits inside the box. Of course, this adds cost, increases required board space, makes thermal management and testing more difficult and introduces additional assembly expense. Another frequently used method is to slow down the switching edges. This has the undesired effect of reducing the efficiency, increasing minimum on, off times, and their associated dead times and compromises the potential current control loop speed.Tony Armstrong, Director of Product Marketing Power Products; © Linear Technology Corporation

Figure 1. LTC3245 Schematic Delivering a Fixed 5V Output from a 2.7V to 38V Input

A few years ago, Linear Technology introduced our LT8614 Silent Switcher® regulator, which delivers the desired effects of a shielded box without using one, while also eliminating many of the above mentioned drawbacks. Nevertheless, in some noise applications, power supply designers simply do not like to use inductor-based regulators due to their associated EMI emissions. At the same time, the use of a linear regulator (aka LDO) may be precluded due to its relatively low conversion efficiency and need for heat sinking. As a result, they can turn to a common alternative, the charge pump. Therefore, we introduced our LTC3245 and LTC3260 to provide designers with another practical alternative solution that sits between these two afore mentioned approaches.

What are the advantages of your Power product and solution? Would you please share this innovative solution with us?

Figure 1. LTC3245 Schematic Delivering a Fixed 5V Output from a 2.7V to 38V Input

A few years ago, Linear Technology introduced our LT8614 Silent Switcher® regulator, which delivers the desired effects of a shielded box without using one, while also eliminating many of the above mentioned drawbacks. Nevertheless, in some noise applications, power supply designers simply do not like to use inductor-based regulators due to their associated EMI emissions. At the same time, the use of a linear regulator (aka LDO) may be precluded due to its relatively low conversion efficiency and need for heat sinking. As a result, they can turn to a common alternative, the charge pump. Therefore, we introduced our LTC3245 and LTC3260 to provide designers with another practical alternative solution that sits between these two afore mentioned approaches.

What are the advantages of your Power product and solution? Would you please share this innovative solution with us?

The LTC3245 is a buck-boost regulator that dispenses with the traditional inductor and uses a switched-capacitor charge pump instead. Its input voltage range is 2.7V to 38V, and it can be used without a feedback divider to produce one of two fixed output voltages, 3.3V or 5V, or programmed via a feedback divider to any output voltage from 2.5V to 5.5V. Maximum output current is 250mA. The LTC3245 is capable of regulating a voltage above or below the input voltage, allowing it to satisfy automotive cold crank requirements, for example. See Figure 1 for its complete schematic. This charge pump is capable of achieving efficiencies of 80% when delivering 5V at 100mA from a 12V source, almost two times higher than that of a linear regulator, making it possible to avoid the space and cost requirements of an LDO with a heat sink. It generates almost three times lower power loss at full load versus an LDO. See Figure 2 for the LTC3245 efficiency and power loss curves. The LTC3245 also has excellent radiated and conducted EMI performance, as show in Figures 3a and 3b. These measurements were taken in a micro chamber in accordance with CISPR22 and CISPR25. As can be seen, when properly decoupled, the LTC3245 does not present any issue when striving to meet government regulations for radiated and conducted emissions. In many industrial, medical and automotive applications, a dual-polarity supply is often needed to operate electronics such as op amps, drivers and sensors. However, there is rarely a dual-polarity supply available at the point of load. It was because of this need, and the lack of a simple-to-use solution, that Linear Technology developed the LTC3260.Figure 2. LTC3245 Efficiency/Power Loss Curve for 12V Input to 5V Out

Figure 3. Radiated (a) and Conducted (b) Emissions of the LTC3245

The LTC3260 is an inverting charge pump DC/DC converter with dual low noise LDO regulator followers that can produce positive and negative supplies from a single 4.5V to 32V input power source, as illustrated in the Figure 4 complete schematic. It can switch between high efficiency Burst Mode® operation and low noise constant current frequency mode, allowing the designer to make an optimum trade-off for the application.

The LTC3260 can supply up to 100mA from the inverted input voltage at its charge pump output, VOUT. This VOUT also serves as the input supply to a negative LDO regulator, LDO-. The charge pump frequency can be adjusted between 50kHz and 500kHz with a single resistor. Each of the LTC3260’s LDOs is capable of supporting up to 50mA loads. And, each LDO has a dropout voltage of 300mV at 50mA, and an output resistor divider network allows the setting of the output voltage. When both regulators are disabled, the shutdown quiescent current is only 2µA.

Figure 3. Radiated (a) and Conducted (b) Emissions of the LTC3245

The LTC3260 is an inverting charge pump DC/DC converter with dual low noise LDO regulator followers that can produce positive and negative supplies from a single 4.5V to 32V input power source, as illustrated in the Figure 4 complete schematic. It can switch between high efficiency Burst Mode® operation and low noise constant current frequency mode, allowing the designer to make an optimum trade-off for the application.

The LTC3260 can supply up to 100mA from the inverted input voltage at its charge pump output, VOUT. This VOUT also serves as the input supply to a negative LDO regulator, LDO-. The charge pump frequency can be adjusted between 50kHz and 500kHz with a single resistor. Each of the LTC3260’s LDOs is capable of supporting up to 50mA loads. And, each LDO has a dropout voltage of 300mV at 50mA, and an output resistor divider network allows the setting of the output voltage. When both regulators are disabled, the shutdown quiescent current is only 2µA.

Figure 4. A 12V Input Supply to ±5V Outputs

Figure 4. A 12V Input Supply to ±5V Outputs