© ALLPCB

PCB |

ALLPCB upgrades its production line further

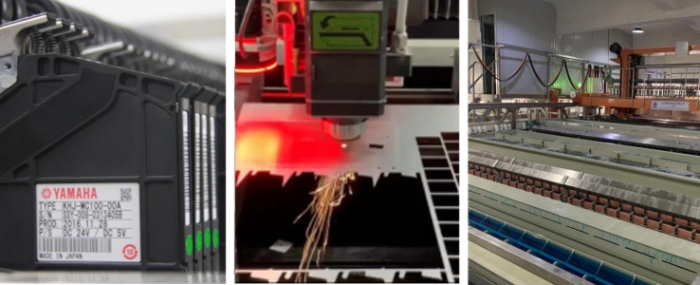

To meet the increase in demand, ALLPCB continues to make improvements to its capacity. Recently the company introduced new machines to further upgrade the production line; a laser cutting machine, Yamaha feed gun, and new copper plating equipment.

The Chinese PCB fabrication manufacturer says in a short update that the company has recently completed yet another upgrade to its production line.

The laser cutting machine is described to be of great significance to ALLPCB. The company says that equipped with this piece of equipment, the aluminum PCB productivity was markedly improved.

One of the main perks is said to be the fact that laser separation processes do not require post-processing in many cases. It even seals the edges of Aluminum PCB to keep them from falling apart. This eliminates the need for post-processing, such as mechanical sealing or polishing, depending on the type of material being processed.

The other – more obvious perk – is that a laser will not wear out; the tool head will not become blunt, which is always good for the cost of continuing operations..

Besides the laser cutter, feed guns from Yamaha and other copper plating equipment have also introduced in order to increase the production capacity, the company writes without elaborating further.