© shawn hempel dreamstime.com

Electronics Production |

A*STAR’s SIMTech rolls out collaborative industry project

A*STAR’s Singapore Institute of Manufacturing Technology (SIMTech) has launched a Collaborative Industry Project (CIP) on Roll-to-Roll Manufacturing of Functional Film and Printed Electronics.

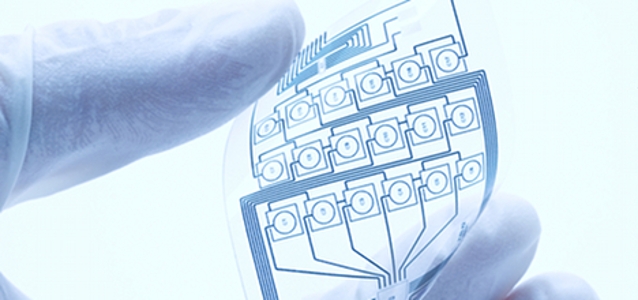

Printed electronics allows manufacturers to print electrical devices on materials such as plastic and it is expected to pave the way for the adoption of low-cost, thin and flexible electronics for products such as flexible displays, smart labels and smart clothing. This market is estimated to grow from USD 9.4 billion in 2013 to USD 76 billion in 2023.

SIMTech’s roll-to-roll manufacturing technology allows electrically-functional materials or conductive inks to be printed on rolls of flexible materials such as polyethylene terephthalate (PET), polycarbonate (PC) and potentially paper and fabric. Extremely versatile, the ultra-thin (<1mm) and lightweight functional surfaces can be printed on a large scale (up to 0.9m width and unlimited length) as well as moulded into 3D shapes.

“The CIP is an effective mechanism to mobilise companies to collaborate with research institutes to develop technology and capabilities for emerging applications. This platform, combined with SIMTech’s relevant expertise and supporting facilities can provide an avenue for industry to tap new market potential,” said Dr Lim Ser Yong, Executive Director of SIMTech.

The SIMTech CIP will focus on three main applications of this production process:

Developing alternative flexible transparent conductive films. Currently, Indium Tin Oxide (ITO) film, a transparent conductor, is essential for building flat panel displays and touch sensors, televisions, computer monitors, tablets and smart phones However, it allows less light to pass through, cannot be shaped with heat, and cracks easily. The CIP will explore the development and manufacturing of alternative films such as silver nano wire or other conductive polymers to replace ITO film.

Creating Flexible Printed Lighting or Electroluminescent Lighting (EL) panels for displays and building facades. These can be flexibly adjusted to customised shapes and are easy to install and maintain. These panels can be overlaid with high-resolution graphics and customised for large surface area applications.

Developing Flexible Printed Electrodes for applications such as multi-touch capacitive sensing and printed antennae. Flexible printed electrodes can be used for near-field communication antenna for hand-held portable devices such as tablets and mobile phones essential for high performance.

Companies participating in the CIP will receive training from SIMTech to acquire relevant technologies in Application Development Kits to capture applications’ opportunities and Process Development Kits to transfer the key roll-to-roll manufacturing processes to equip them to be future manufacturers of printed electronics and functional film using SIMTech-developed technologies. 12 companies are participating in the 18-month CIP; seven of which are small and medium sized enterprises and five are multinationals.