© Nordson

Electronics Production |

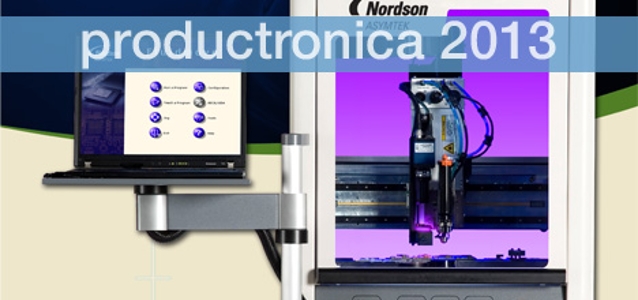

New high speed, high accuracy, precision dispensing system

Nordson ASYMTEK will introduce the Spectrum II at Productronica this year, marking the 6-year anniversary of the introduction of the Spectrum series of high-speed, high-accuracy dispensing platforms.

EDITOR'S NOTE_ This press release was published as part of the evertiq productronica coverage.

Nordson ASYMTEK Munich, November 12 – 15th, 2013 Hall A2, Booth 339 New Munich Trade fairThe Spectrum II S2-900 Series leverages the same small footprint of 600mm x 1321mm as the original Spectrum to provide maximum productivity with minimum manufacturing floor space, but improves the precision, accuracy, and speed of the system to rival much larger platforms. "Miniaturization trends in semiconductor applications continue to push the limits of fluid dispenser capabilities to accurately dispense into smaller spaces between board components, camera modules, and die. Customers are increasingly more concerned with consistency and straightness of their dispensed lines, not just dot A to dot B system motion, in order to shrink their end applications," explained Garrett Wong, Spectrum Series product manager, Nordson ASYMTEK. "MEMS sealant lines and solder paste applications challenge dispenser capabilities in precision Z-gap control and line path accuracy to achieve their required thin line widths and small dot sizes. The new Spectrum II product family meets the needs of this market by driving mechanical and software improvements to achieve ultimate precision and accuracy in all three axes -- X, Y, and Z -- at speeds up to 30,000 dots per hour with a minimal footprint to maximize productivity per square meter." The new Spectrum II system introduces features that enable new levels of precise fluid dispensing:

- Precision Z-axis performance, formerly only offered as an option on Nordson ASYMTEK's large area platform, has been integrated into every Spectrum II system to enable consistent <200µm dots and solder paste line dispensing for MEMS and HDD assembly.

- Tilt Jetting capability for precision coating and underfill in hard to reach areas, providing up to 30-degree tilt with most valves. Underfill can get closer to the die edge for tighter keep-out zones.

- Automatically Adjusting Dual Simultaneous Dispensing minimizes downtime and operator intervention by automatically adjusting valve positions for workpiece skew while dual simultaneous valves decrease the cost of units per hour.

- Higher Brightness Vision Lighting creates increased contrast for difficult applications, improving fiducial find accuracy and consistency.

- Higher Accuracy Non-Contact Laser Height Sensors improve detection of surface heights and allow tighter dispense gaps for thinner dispense lines.