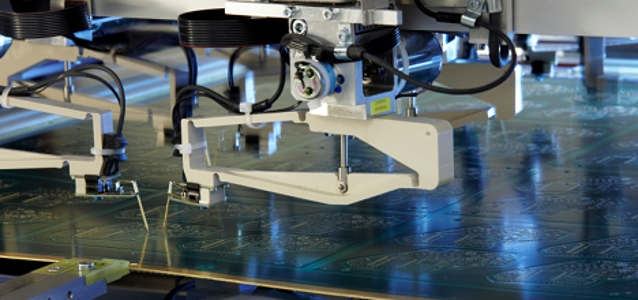

© Aspocomp

PCB |

Interview: Aspocomp CEO Sami Holopainen

Aspocomp's CEO Sami Holopainen talks about the company's new factory in Teuva, Finland, and how it plans to expand capability.

Based in Finland, Aspocomp had a positive last year, growing both in profit and sales year-on-year. Profit for the company grew to EUR 4.1 million, up from 1.8 million, and sales grew an impressive 26 percent.

They also purchased a factory owned by Cibo-Print Oy in Teuva.

The company primarily serves customers in Northern Europe - Sweden, Finland and Germany – providing prototyping that requires quick delivery times.

“We have placed ourselves in the position where we don't really compete with the cheaper markets,” says Holopainen on the company's recent progress. “Our offering is actually the combination of the product itself and the delivery time, and then the extensive services. We are serving the R & D departments of the companies that are designing and selling electronic devices”.

In order to provide quick delivery times the company needed more capacity than was available in their factory at Oulu - a primary driver in their decision to purchase an additional factory in Teuva.

“The reason why we purchased the factory was we wanted to broaden our product portfolio and also increase our capacity. For the two years - 2010, 2011 - we've been running pretty high capacity using the space in our old factory. Our company's competitive advantage is speed and fast delivery so that requires the factory to have capacity flexibility,” explains Holopainen. “We are working on a time issue and that requires that we can have some extra capacity so that we can react very fast when the customer orders a quick order from us. And we have been just a little bit suffering that the capacity utilization was a bit too high”.

“We also knew this factory because it had actually been an Aspocomp factory before. So there are still employees from the key office here that already been Aspocomp employees. We saw this as a very easy nurture project. So that we get more capacity, more customers and the product portfolio is wider”.

Aspocomp have retained all of the factory's 42 employees and, for a prototype services focused company that runs 24/7 shifts, retaining staff with experience is becoming incredibly important.

“It's definitely important to us. In order to be quick in terms of the production you have to have employees down on the shop floor that are empowered and that take the initiative. They make sure that products are moving in the shop floor,” says Holopainen. “This is a business that takes time to learn, so retaining the good staff is very critical for our company”.

Holopainen says that this year the company intends to invest more than average, continuing to build technological capability. “How we will work in the future is that we will keep on upgrading technologically our old factory but at the same time we can move some old machinery to the new factory... So we are able to lift the technological capabilities of both factories at the same time”.